MTR

RACK CONVEYOR DISHWASHERS

MTR

RACK CONVEYOR

DISHWASHERS

with a wide range of conversion and retrofitting options. For hygienic wash

results and an economic washing process. And everything falls into place.

THE DISHWASHING SYSTEM FOR

COMMERCIAL KITCHENS

Peak times with up to 355 racks per hour. Filled with plates and cutlery, cups and glasses. And stacks of trays. And plenty of reusable cups and bowls in between. Different volumes of wash items distributed throughout the day – typical for restaurants and hotels, small and medium-sized canteens, hospitals and nursing facilities. Or service stations and caterers. In this area, the MTR series rack conveyor dishwashers set new standards: The machine architecture is based on a consistently well-designed modular system. This allows the machine to be customised to today’s requirements more precisely than ever before. And: with the option of flexible retrofitting, it can also be adapted to the requirements of tomorrow. This means that the MTR adapts perfectly to every new situation and provides not only first-class washing performance but also maximum investment security.

MTR PRODUCT BENEFITS

FIRST-CLASS WASH RESULTS

Whether you have small or large wash items, and whether you are working at peak times or with a large amount of dirt: the powerful warewashing system and effective multi-filtration of the MTR series ensure consistently high wash results. Each zone helps to ensure first-class cleanliness and excellent drying. This ensures that your wash items come out of the machine spotless.

HIGH ECONOMIC EFFICIENCY

Washing is particularly economical with the MTR series. Water is used in a targeted and sparing way. Energy is used several times with the help of heat recovery. And if there is room for optimisation in the washing process, the machine gives proactive advice. All this provides efficient warewashing operation, saves resources and reduces your operating costs to a minimum.

MAXIMUM HYGIENE SAFETY

Whether you have small or large wash items, and whether you are working at peak times or with a large amount of dirt: the powerful warewashing system and effective multi-filtration of the MTR series ensure consistently high wash results. Each zone helps to ensure first-class cleanliness and excellent drying. This ensures that your wash items come out of the machine spotless.

CONVENIENT OPERATION

Washing is particularly economical with the MTR series. Water is used in a targeted and sparing way. Energy is used several times with the help of heat recovery. And if there is room for optimisation in the washing process, the machine gives proactive advice. All this provides efficient warewashing operation, saves resources and reduces your operating costs to a minimum.

COMPLETE FLEXIBILITY. MAXIMUM INVESTMENT SECURITY.

Anyone who invests in a warewasher today wants to make the right decision for tomorrow. But what will the future bring? How much will the business expand? Will the environment change? Will new and innovative features be launched? With a MTR series rack conveyor dishwasher, you can relax and let these developments come to you. The machine architecture is based on a modular system and allows individual zones and components to be flexibly combined with each other. This has two big advantages. Firstly, the machine can be configured to perfectly match your needs and equipment requirements. And secondly, the machine can be converted or retrofitted at a later date. This means that the MTR series offers you the greatest possible security in planning and investment. To put it another way: when your business grows, the machine grows with it.

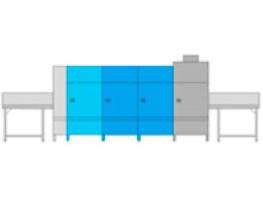

The most powerful MTR

- maximum machine configuration

- for the highest requirements

- maximum capacity of 355 racks per hour

The most powerful MTR

- maximum machine configuration

- for the highest requirements

- maximum capacity of 355 racks per hour

The most powerful MTR

- maximum machine configuration

- for the highest requirements

- maximum capacity of 355 racks per hour

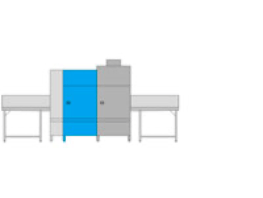

2 Tanks

Model

MTR S

Diners/h*

approx. 200

Racks/h

max. 190

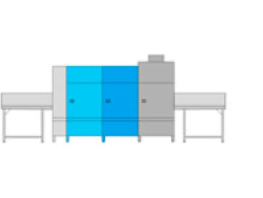

3 Tanks

Model

MTR M

Diners/h*

approx. 300

Racks/h

max. 275

4 Tanks

Model

MTR L

Diners/h*

approx. 400

Racks/h

max. 355

2 Tanks

3 Tanks

4 Tanks

Model

MTR S

MTR M

MTR L

Diners/h*

approx. 200

approx. 300

approx. 400

Racks/h

max. 190

max. 275

max. 355

*Deviations possible depending on operating mode and wash item volume

*Deviations possible depending on operating mode and wash item volume

PRODUCT FEATURES

OF THE MTR RACK CONVEYOR DISHWASHER

CONNECTED WASH

CONNECTED WASH can be used to analyse and evaluate all important machine data from the networked MTR and to access it from anywhere. If there is scope for optimisation in the washing process, CONNECTED WASH indicates this with specific recommendations for action, which increases economic efficiency. If a critical errors occurs, the machine automatically sends a notification, ensuring absolute hygiene safety and greater efficiency. Automatic updates ensure that the software on the machine is always up to date and that new functions are available immediately.

CONNECTED WASH

CONNECTED WASH can be used to analyse and evaluate all important machine data from the networked MTR and to access it from anywhere. If there is scope for optimisation in the washing process, CONNECTED WASH indicates this with specific recommendations for action, which increases economic efficiency. If a critical errors occurs, the machine automatically sends a notification, ensuring absolute hygiene safety and greater efficiency. Automatic updates ensure that the software on the machine is always up to date and that new functions are available immediately.

CONNECTED WASH

CONNECTED WASH can be used to analyse and evaluate all important machine data from the networked MTR and to access it from anywhere. If there is scope for optimisation in the washing process, CONNECTED WASH indicates this with specific recommendations for action, which increases economic efficiency. If a critical errors occurs, the machine automatically sends a notification, ensuring absolute hygiene safety and greater efficiency. Automatic updates ensure that the software on the machine is always up to date and that new functions are available immediately.

CONNECTED WASH

CONNECTED WASH can be used to analyse and evaluate all important machine data from the networked MTR and to access it from anywhere. If there is scope for optimisation in the washing process, CONNECTED WASH indicates this with specific recommendations for action, which increases economic efficiency. If a critical errors occurs, the machine automatically sends a notification, ensuring absolute hygiene safety and greater efficiency. Automatic updates ensure that the software on the machine is always up to date and that new functions are available immediately.

CONNECTED WASH

CONNECTED WASH can be used to analyse and evaluate all important machine data from the networked MTR and to access it from anywhere. If there is scope for optimisation in the washing process, CONNECTED WASH indicates this with specific recommendations for action, which increases economic efficiency. If a critical errors occurs, the machine automatically sends a notification, ensuring absolute hygiene safety and greater efficiency. Automatic updates ensure that the software on the machine is always up to date and that new functions are available immediately.

CONNECTED WASH

CONNECTED WASH can be used to analyse and evaluate all important machine data from the networked MTR and to access it from anywhere. If there is scope for optimisation in the washing process, CONNECTED WASH indicates this with specific recommendations for action, which increases economic efficiency. If a critical errors occurs, the machine automatically sends a notification, ensuring absolute hygiene safety and greater efficiency. Automatic updates ensure that the software on the machine is always up to date and that new functions are available immediately.

CONNECTED WASH

CONNECTED WASH can be used to analyse and evaluate all important machine data from the networked MTR and to access it from anywhere. If there is scope for optimisation in the washing process, CONNECTED WASH indicates this with specific recommendations for action, which increases economic efficiency. If a critical errors occurs, the machine automatically sends a notification, ensuring absolute hygiene safety and greater efficiency. Automatic updates ensure that the software on the machine is always up to date and that new functions are available immediately.

CONNECTED WASH

CONNECTED WASH can be used to analyse and evaluate all important machine data from the networked MTR and to access it from anywhere. If there is scope for optimisation in the washing process, CONNECTED WASH indicates this with specific recommendations for action, which increases economic efficiency. If a critical errors occurs, the machine automatically sends a notification, ensuring absolute hygiene safety and greater efficiency. Automatic updates ensure that the software on the machine is always up to date and that new functions are available immediately.

CONNECTED WASH

CONNECTED WASH can be used to analyse and evaluate all important machine data from the networked MTR and to access it from anywhere. If there is scope for optimisation in the washing process, CONNECTED WASH indicates this with specific recommendations for action, which increases economic efficiency. If a critical errors occurs, the machine automatically sends a notification, ensuring absolute hygiene safety and greater efficiency. Automatic updates ensure that the software on the machine is always up to date and that new functions are available immediately.

CONNECTED WASH

CONNECTED WASH can be used to analyse and evaluate all important machine data from the networked MTR and to access it from anywhere. If there is scope for optimisation in the washing process, CONNECTED WASH indicates this with specific recommendations for action, which increases economic efficiency. If a critical errors occurs, the machine automatically sends a notification, ensuring absolute hygiene safety and greater efficiency. Automatic updates ensure that the software on the machine is always up to date and that new functions are available immediately.

CONNECTED WASH

CONNECTED WASH can be used to analyse and evaluate all important machine data from the networked MTR and to access it from anywhere. If there is scope for optimisation in the washing process, CONNECTED WASH indicates this with specific recommendations for action, which increases economic efficiency. If a critical errors occurs, the machine automatically sends a notification, ensuring absolute hygiene safety and greater efficiency. Automatic updates ensure that the software on the machine is always up to date and that new functions are available immediately.

CONNECTED WASH

CONNECTED WASH can be used to analyse and evaluate all important machine data from the networked MTR and to access it from anywhere. If there is scope for optimisation in the washing process, CONNECTED WASH indicates this with specific recommendations for action, which increases economic efficiency. If a critical errors occurs, the machine automatically sends a notification, ensuring absolute hygiene safety and greater efficiency. Automatic updates ensure that the software on the machine is always up to date and that new functions are available immediately.

CONNECTED WASH

CONNECTED WASH can be used to analyse and evaluate all important machine data from the networked MTR and to access it from anywhere. If there is scope for optimisation in the washing process, CONNECTED WASH indicates this with specific recommendations for action, which increases economic efficiency. If a critical errors occurs, the machine automatically sends a notification, ensuring absolute hygiene safety and greater efficiency. Automatic updates ensure that the software on the machine is always up to date and that new functions are available immediately.

CONNECTED WASH

CONNECTED WASH can be used to analyse and evaluate all important machine data from the networked MTR and to access it from anywhere. If there is scope for optimisation in the washing process, CONNECTED WASH indicates this with specific recommendations for action, which increases economic efficiency. If a critical errors occurs, the machine automatically sends a notification, ensuring absolute hygiene safety and greater efficiency. Automatic updates ensure that the software on the machine is always up to date and that new functions are available immediately.

CONNECTED WASH

CONNECTED WASH can be used to analyse and evaluate all important machine data from the networked MTR and to access it from anywhere. If there is scope for optimisation in the washing process, CONNECTED WASH indicates this with specific recommendations for action, which increases economic efficiency. If a critical errors occurs, the machine automatically sends a notification, ensuring absolute hygiene safety and greater efficiency. Automatic updates ensure that the software on the machine is always up to date and that new functions are available immediately.

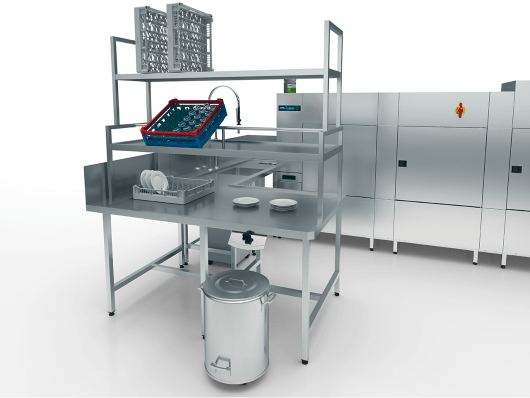

CHANGING THE GAME OF EFFICIENT AND ERGONOMIC WASHING

Creating a successful commercial kitchen requires clever spatial planning, energy-efficient technology, streamlined operating processes, and strict hygiene standards. The MTF series of high-performance conveyor dishwashers offers a flexible and customisable solution for kitchen planners to develop innovative operating concepts that cater to the unique needs of each customer.

MODULAR ARCHITECTURE FOR GREATER FLEXIBILITY

Creating a successful commercial kitchen requires clever spatial planning, energy-efficient technology, streamlined operating processes, and strict hygiene standards. The MTF series of high-performance conveyor dishwashers offers a flexible and customisable solution for kitchen planners to develop innovative operating concepts that cater to the unique needs of each customer.

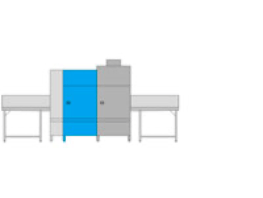

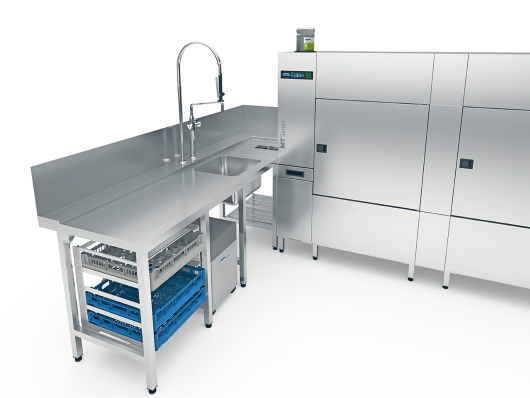

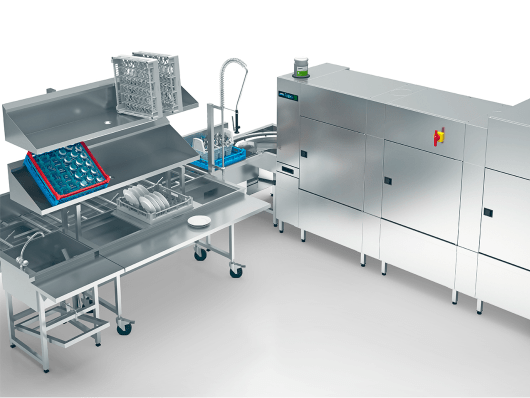

MTR rack conveyor warewasher with straight drying zone

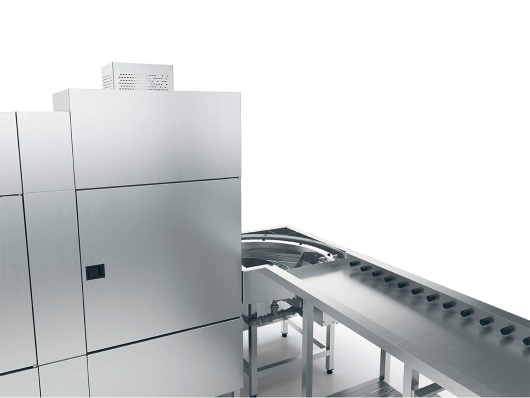

Corner conveyor 90° with outlet roller table